Safety Interlocks with Solenoid Controlled Guard Locking

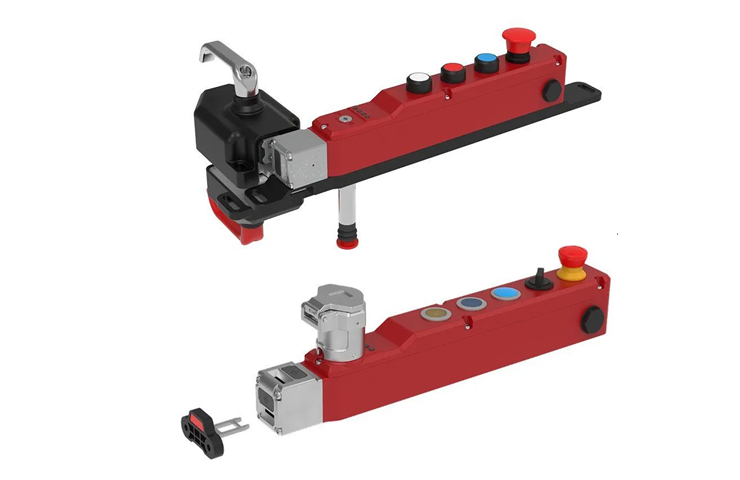

Safety interlocks with guard locking provide reliable position detection for movable guards and feature a locking mechanism that keeps the guard securely closed until the hazard is resolved. These tongue-operated switches are installed on the leading edge of sliding or hinged machine guards, offering positively operated switching contacts and a tamper-resistant cam interlock mechanism.

IDEM’s safety interlocks securely mount to the guard or machine frame, with the actuator attached

to the movable guard part and aligned with the switch entry. The actuator engages a cam

mechanism within the switch head, closing the safety contacts when inserted and enabling the

machine’s start circuit. The solenoid then opens the safety contacts, breaking the machine

circuit and allowing the guard to open. These switches can include safety timers for delayed

opening in machines requiring a run-down period, and standard models automatically lock when the

actuator inserts, unlocking only with solenoid power.

Depending on the application’s risk assessment, these switches can operate alone for positively

operated contacts per EN60947-5-1 or combine with dual-channel safety monitoring relays to

achieve up to PLe Category 4 (ISO13849-1) or SIL3 (EN62061). Safety interlocks with guard

locking and OSSD outputs ensure the highest machine safety, especially for applications

requiring PL e, with real-time status feedback for continuous monitoring.

Our Safety Interlocks with Guard Locking are ideal for most industrial applications, including

but not limited to: